Injection Molding: High-Precision, High-Volume Plastic Manufacturing

Injection molding is a versatile and efficient manufacturing process ideal for mass-producing complex, durable plastic parts with tight tolerances and consistent quality. From automotive components to medical devices, this process enables large-scale production with exceptional detail and strength.

Why Choose Injection Molding?

Injection molding is one of the most widely used plastic manufacturing processes due to its speed, precision, and cost-effectiveness. It allows for the creation of intricate designs with minimal waste, making it ideal for high-volume production runs.

Key advantages of injection molding:

Fast cycle times for high-volume output

Low per-unit production costs

Ability to create complex and detailed components

Our Injection Molding Capabilities

At Concept Sales Inc., we partner with top manufacturers to provide high-quality, injection-molded solutions for various industries. Our partners offer:

Advanced Machinery for High-Volume Production

Equipped with 16 injection molding machines ranging from 50 to 610 tons, allowing for the production of both small and large components.

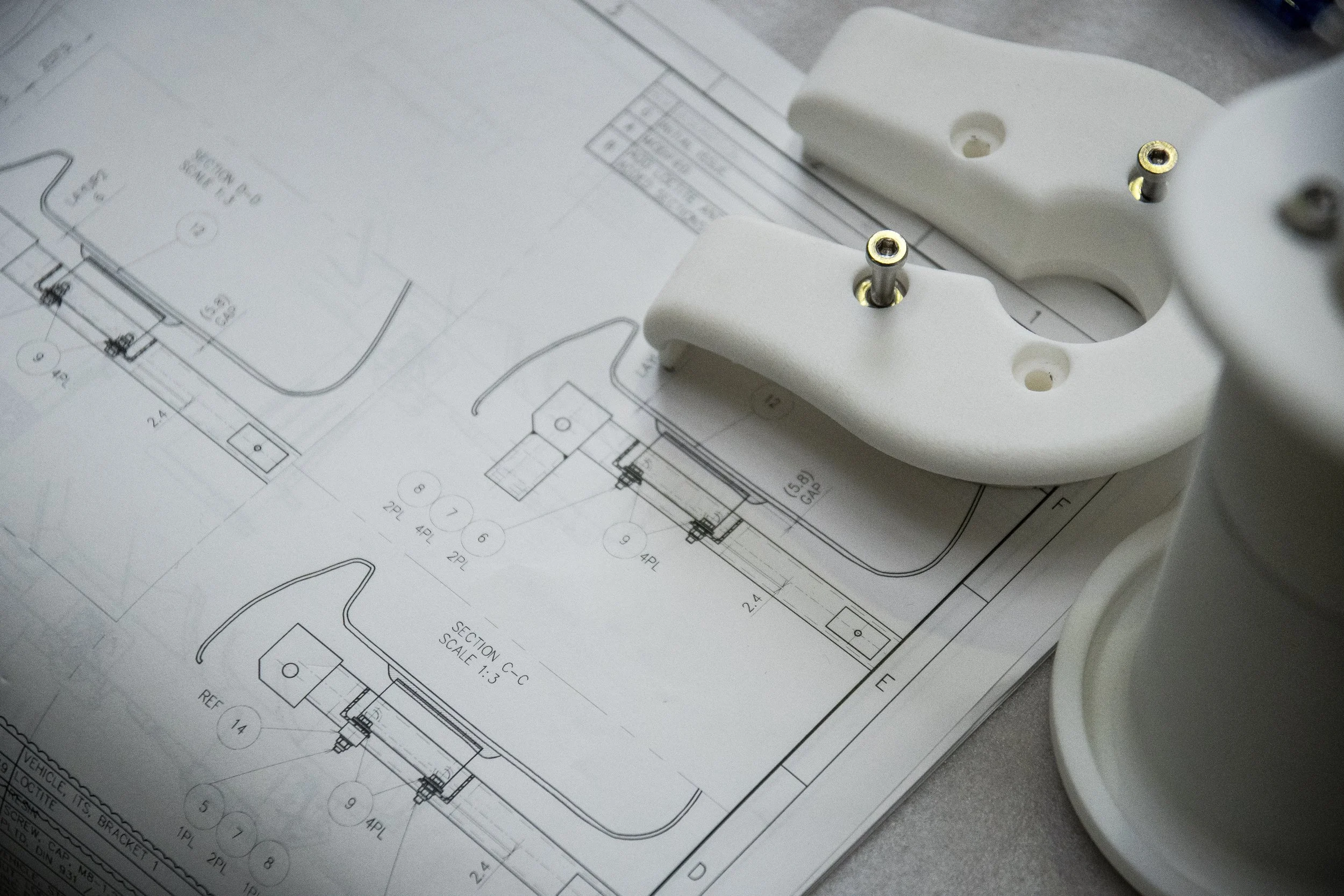

Precision Engineering & Mold Design

Our in-house engineering team provides custom mold design and optimization, ensuring high-quality, cost-effective solutions tailored to your specifications.

Our quality assurance team utilizes rigorous testing procedures to ensure consistency, durability, and precision in every manufactured part.

Stringent Quality Control & Testing

We maintain in-house mold maintenance facilities to extend the life of your molds, ensuring continued performance and cost efficiency.

Mold Maintenance & Longevity

We offer assembly, printing, and finishing services to provide a turnkey solution, reducing production time and streamlining logistics.

Comprehensive Secondary Services

Looking for cost-effective, high-precision plastic manufacturing?

Injection molding is the perfect solution for large-scale, detailed production. Contact us today to discuss your project needs.

Best Use Cases for Injection Molding

Mass production of detailed plastic components

Consumer, automotive, and industrial applications

Products requiring durability and consistency

Common Applications

Automotive components

Consumer electronics

Medical devices

Packaging & enclosures